Customs Rules for Bringing Plants or Seeds

Record Keeping and Maintenance

My filing system for import documents has become increasingly sophisticated over the years. What began as a simple folder is now a searchable digital database with cloud backups. I've found that well-organized records make annual permit renewals much smoother.

Every six months, I review and purge outdated documents according to retention policies. But I keep digital archives of everything - you never know when you'll need to reference an old import for compliance purposes.

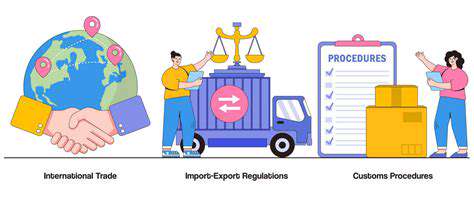

Oral appliances represent just one example of how specialized equipment requires proper documentation for international transport. The same meticulous approach needed for plant imports applies to many regulated goods crossing borders.

The Role of Pest and Disease Prevention in Import Regulations

Pest Prevention Strategies

Stopping pests at the border requires multiple defensive layers. Inspectors look for telltale signs like leaf damage, unusual markings, or the pests themselves. I've seen cases where a single aphid spotted during inspection prevented a major infestation. The most effective strategies combine visual inspections with advanced detection methods.

Some countries now use X-rays and scent detection dogs at ports of entry. These methods can reveal pests hidden deep in packaging or soil that visual inspections might miss. The technology keeps improving, but so do the pests' abilities to hitch rides undetected.

Disease Prevention Techniques

Plant diseases often travel invisibly, making them particularly dangerous. I recall a shipment of citrus trees that looked healthy but carried a devastating canker disease. Only laboratory testing revealed the problem before the trees could enter the country.

Some nations require pathogen testing for high-risk plants. These tests might involve DNA analysis or growing samples in controlled conditions to check for symptoms. The process adds time and cost, but it's far cheaper than dealing with an outbreak later.

Integrated Pest Management (IPM)

The smartest importers use IPM principles before plants even reach the border. I advise clients to implement preventive measures at the source - using beneficial insects, proper sanitation, and resistant varieties. This multi-pronged approach reduces reliance on chemical treatments that might not be allowed in the destination country.

One nursery I work with has reduced its pest problems by 80% through IPM. Their plants now clear customs faster because inspectors recognize their rigorous prevention protocols.

Biological Control Methods

Nature provides some of the best pest control solutions. I've seen tiny parasitic wasps decimate whitefly populations in quarantine greenhouses. These natural predators often work better than chemicals because pests can't develop resistance to being eaten.

Some countries specifically approve certain beneficial insects for import. The paperwork differs from pest species, but the approval process ensures these biological controls won't become invasive themselves.

Cultural Practices for Prevention

How plants are grown affects their pest and disease risks. Overcrowded plants become pest magnets, while proper spacing promotes health. I've walked through nurseries where simple changes in irrigation reduced fungal problems dramatically.

Smart growers adjust practices based on import requirements. If a destination country has strict rules about soil-borne pathogens, they might switch to hydroponic systems for export plants.

Sanitation and Hygiene Practices

Cleanliness matters more than most people realize in plant importation. I disinfect tools between handling different shipments and require workers to change clothes after contact with new arrivals. One contaminated pruning shear can spread problems throughout a facility.

Some countries mandate specific sanitation protocols for imported plants. These might include approved disinfectants or required quarantine periods before plants can be repackaged.

Monitoring and Evaluation

Vigilance doesn't end when plants clear customs. I recommend monitoring imports for several growth cycles to catch any delayed symptoms. Some pests or diseases take weeks to become apparent.

Keeping detailed health records helps identify patterns. If multiple shipments from the same source develop issues, it might indicate a problem at the origin that needs addressing.

Penalties for Non-Compliance with Regulations

Consequences of Importing Plants Without Proper Documentation

Attempting to bypass plant import regulations can backfire spectacularly. Fines often start in the thousands of dollars and can escalate quickly for repeat offenses. I've witnessed cases where penalties exceeded the value of the shipment by tenfold. Worse, unauthorized plants typically get destroyed - a total loss for the importer.

The financial hit often comes with administrative consequences. Offenders might face increased scrutiny on future shipments or temporary bans from importing. Some countries maintain blacklists of problematic importers.

Sanctions for Introducing Invasive Species

The penalties turn particularly severe when non-native plants escape into the wild. One importer faced million-dollar fines after his unauthorized bamboo planting spread uncontrollably. Courts can order offenders to fund eradication efforts, which often cost far more than proper import procedures would have.

Criminal charges become possible in egregious cases. Several countries have jailed individuals for knowingly smuggling prohibited plants that later caused ecological damage.

Potential for Quarantine and Treatment

Undocumented plants don't just face destruction - they might get quarantined at the importer's expense. I've seen bills for specialized quarantine facilities run hundreds of dollars per day. Treatment costs add up quickly too, especially when fumigation or other intensive methods are required.

Impact on Business Reputation and Future Imports

A single violation can tarnish an importer's reputation for years. Customs agencies share information internationally, so problems in one country can affect operations elsewhere. I know businesses that lost major contracts after appearing on non-compliance lists.

Permit applications ask about past violations. Answering yes can trigger additional requirements or outright denials. It's not just about fines - it's about maintaining access to global markets.

Liability for Damages Caused by Non-Compliant Imports

When invasive plants escape, the financial consequences can be staggering. Courts have ordered importers to pay for ecosystem restoration, lost agricultural revenue, and even decreased property values. One case in Australia resulted in a $20 million judgment against an importer whose plants contaminated nearby farms.

Insurance rarely covers these liabilities if the import violated regulations. That means the financial risk falls entirely on the importer.

Administrative and Legal Proceedings

Fighting a plant import violation can consume months or years. The process typically begins with administrative hearings but can escalate to civil or criminal court. I've advised clients through cases where legal fees exceeded the original fines.

The paperwork burden alone can overwhelm small businesses. Responding to information requests, preparing defenses, and complying with ongoing monitoring requirements creates significant operational drag.

![Planning a Family Camping Trip [Beginner's Guide]](/static/images/27/2025-04/MakingtheMostofYourCampingExperience.jpg)